Hardinge Hsl Lathe Manual

HARDINGE BROTHERS, INC. ELMIRA check the part description to make certain the assembly and/or individual part applies to your machine. .. Bed. 2. Screw. 2. Washer. Front Screw. Lock Washer. 6. 14 D V. 0 0 1 0 2 1 4. D V B 0 0 0 9 7 7 6. 0 5 5 0 3 0 5. N 3 7 0 0 0 0 7 3 6. 5 p. 0 0 0 6 4 3. HARDINGE DV59 DSM59 Lathe Part Manual DV DSM [Misc.] on Amazon. com. *FREE* shipping on qualifying offers. Number of Pages: 15 This is a. DV59 Precision Lathe and DSM This is a reproduction, not a photocopy, of an original Hardinge DV59 Precision Lathe and DSM59 Second Operation.

| Author: | Voodoogul Tojahn |

| Country: | Republic of Macedonia |

| Language: | English (Spanish) |

| Genre: | Business |

| Published (Last): | 6 November 2016 |

| Pages: | 305 |

| PDF File Size: | 13.1 Mb |

| ePub File Size: | 14.83 Mb |

| ISBN: | 965-6-76740-761-2 |

| Downloads: | 81570 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Fenrirg |

My manuals are not photocopies. Must be a trick I am missing.

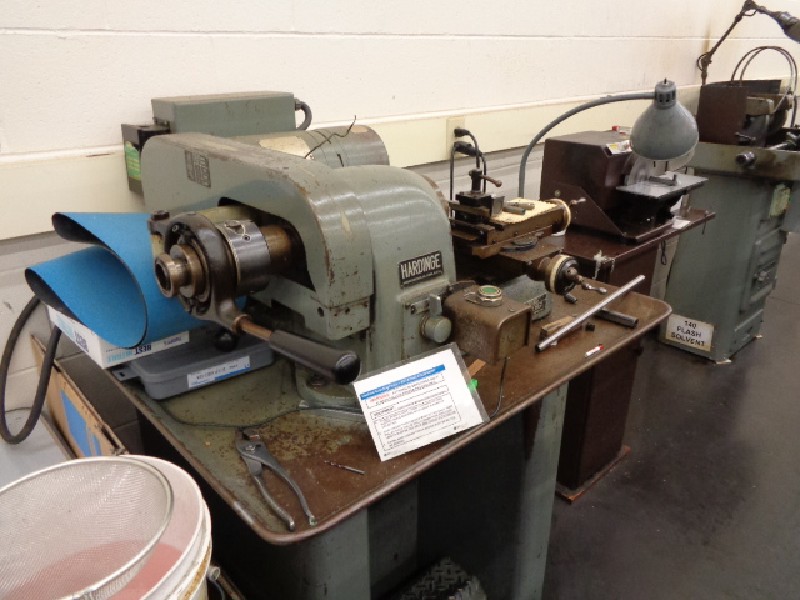

Hardinge DV, DSM, TFB-H, HC-AT, HSL & HC Lathes

Hardinge Hsl Lathe Manual Recognizing the exaggeration ways to acquire this books hardinge hsl lathe manual is additionally useful. You have remained in right site to begin getting this info. Get the hardinge hsl lathe manual member that we have enough money here and check out the link. You could buy lead hardinge hsl lathe manual or acquire it. The HSL has the same spindle and front bearing retainer as the DSM and DV59, so the stamped steel nose protector and vertical cutoff slide are the same for all three models. I have several old Hardinge lathes with the outer spindle taper very badly worn from polishing operations, so the protector is a very wise idea. Hardinge CONQUEST T51 T65 CNC Lathes Parts List – GE Fanuc 18T Bridgeport Series 1 Milling Machine Installation Operator Maintenance Parts List Manual Hardinge Cobra 65 CNC Lathes Parts List – GE Fanuc 21.

Will watch both of your mahual closely, so I don’t make the same mistakes! Due to the size of this slide, I do not like to modify this slide but intend to proceed as follows: I have the exact same model, except mine has a turret tailstock. The motor brake will need to be removed 7.

I think another fellow has the same style as you, I have been surprised with how many different variations there are and they are all called DV although probably different version numbers. Loosen motor plate as far as it will go Belt tensioner 5. Run speed adjustment to top 2. See Details on eBay Watch Contact. Welcome rrossey, A couple of quick issues, The V-Way on these are bolted to the bed, these bolts are only about 1.

This system attaches to the spind Remove both the lead screws and dv-95 with rolled ball screws and two nuts on each screw.

These do not come out easily on the handwheel side of the head like the newer model. This manual contains a complete set of crossection part diagrams with descriptions.

Swing Over the Bed: Again the shims and spacers are to be provided to eliminate back-lash. Fully functional and working.

I do have the carriage blocks drawn up and tool paths for when they get db-59. I propose to complete this project in two phases Phase I I will keep the head and spindle of the DV 59 lathe as it is, driven by 1 HP induction motor.

Will load on your truck for free! The time now is It has the head stock that clamps manuual the bed not bolts to.

I changed belts on a Hardinge years ago. Super high amount of views. Stepper motors will be mounted on both axis of the table, directly coupled to the ball screws if space permits, or else through timing belt and pulleys. The bed of this lathe is having a longitudinal slot in the middle of the bed and chamfers through out the length. Tags for this Thread anotheravailablebedcncdvforumfourkeeplatheoperasightable. I will be starting a new thread in a couple of days after completing a concept drawing to go along with it.

Which is the better way?

Hardinge Dv59 Later Model Metal Lathe Operator’s Manual 0871

The above makes it not impossible but difficult to use as is. Read over relative threads, not just this one but others here as well and then you will be in a better position to begin how best to accomplish the conversion.

It has no major wear that could affect its performance. From everything I read the only draw back to servos is that they can cost more then steppers.

I believe this manual will be a valuable mznual of knowledge that will provide a lot of helpful information that is often hard to find. I maintain a high standard of quality in my reproductions. Spindle Nose Cover Guard.

I do not carry additional parts for machinery, except for what is listed. The guide ways of the manyal table slides will be scraped and improved upon as required, to a reasonable condition.

These V-ways are also harder then the gates of hades, not going to slot easily with conventional means. I built a small lathe using a precision x-y table and stepper motors that I use every day. Stainless Steel Size of Components: Roll top belt off sleeve.

Mine actually has the bar with the wheel that goes through the spindle and screws onto the collet, but it is missing the entire lever arm assembly. The table is to be mounted on the lathe bed and fixed to the bed so that the cross slide – 7.

Hardinge Hsl Lathe Manual Free